| | | | Manual Boost Controller Instructions

First and foremost, realize that excessive boost can destroy an engine instantly !!!!!

TIP: Tune your Engine Management tables to very conservative values so that if an over boost condition occurs there will be very low timing values and very rich fueling in the overboost MAP areas. THis will save the engine and also make it very obious if boost has exceeded the target level.

You may want to read the Boost Solenoid page first to understand how boost controllers work.

Let's get started......read all of this before getting started.

The boost valve leaves the factory with the adjuster at a very low boost setting (about 5 psi).

In this low setting there will be about a 1/2" of threads exposed above the top of the nut.

You can check the starting low setting by using your breath to blow into the inlet port (the barb furthest from the adjuster end). While blowing loosen the adjuster until you hear air escaping. That is the low setting. A bicycle pump is also a good way to get a basic boost setting established.

Be carefull to hold the valve upright if you unscrew the adjuster all the way....there is a spring and ball that could fall out....

There is a small vent hole in the outlet fitting (to wastegate), do not let this become covered or blocked.

It is best to install /plumb the controller into your engine while the boost valve is set in the low position.

Make sure your hoses are of the correct size and will not slip off the barbs, if they do you will have a possibly damaging over-boost condition.

To be sure, clamp the hose to the barbs in some way. (Hose clamps,safety wire,cable ties etc)

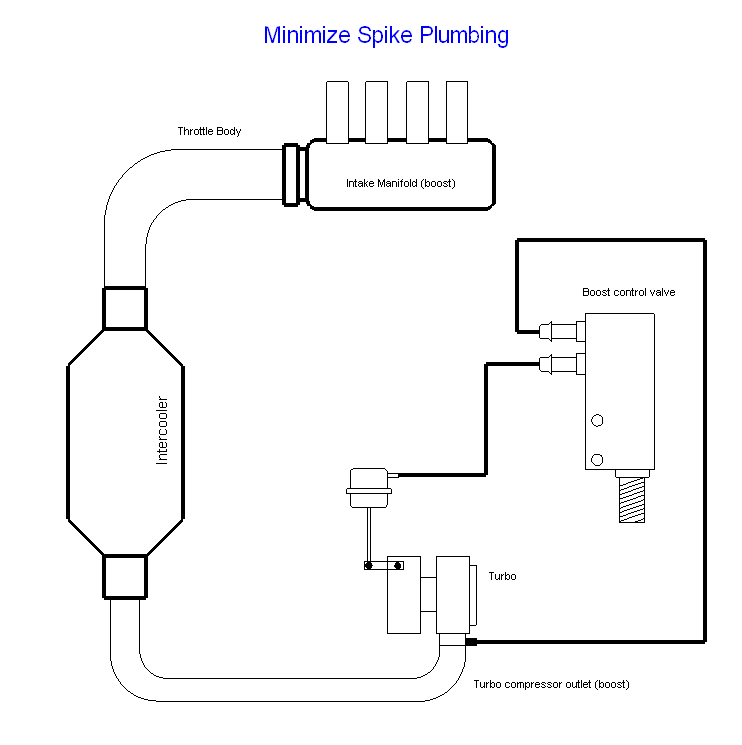

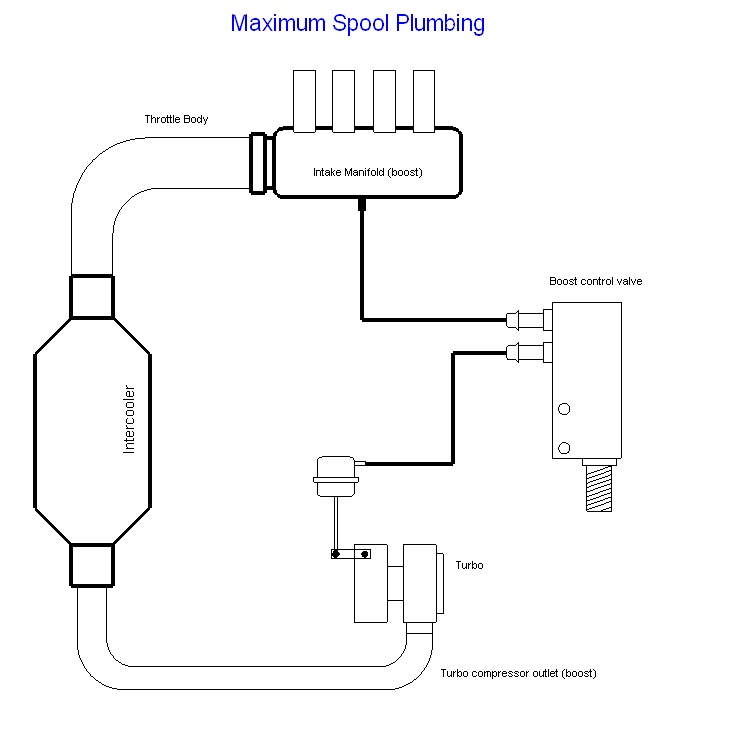

Plumb the boost valve like this:

Double check that all fittings and hoses are tight and do a test pull in 3rd gear.

Start at an engine RPM that is lower than your spool point (about 2000 rpm) and open the throttle all the way, KEEP AN EYE ON THE BOOST GAUGE as boost builds.

If the boost goes higher than intended immediatley let off the accelerator.

Because the boost controller is set low you should not be getting very much boost, about 5-10 psi.

If you get higher than intended boost double check your plumbing and make sure the connections to the controller are nor reversed.

If you want to check your turbo system and rule out any effect the boost controlller may have, eliminate the boost controller by connecting your wastegate directly to your boost source (turbo compressor outlet or intake manifold). You can also do this by inserting a straight connector in place of the boost valve .

Assuming the boost was too low turn the adjusting screw in. One full turns equals about 2 psi boost increase once it is in the active range. DO repeat test drives until you slowly reach your desired boost setting.Boost may nor increase until you get into the active range, after that point turning the screw in will always increase the boost.

Do not turn the adjustment screw in too far, once the spring inside is fully collapased (coil bound) any further forcing will damage the internal parts (contact us for replacements).

The end of the adjuster has a hex socket, but it can easily be turned by hand, it moves easily, if it doesn't you are probably at fiull range, do not turn it further.

The boost range is approximatley 5- 30 psi, but it depends on the vehicle, keep in mind that you are responsible for determining how much boost is safe.

We have high boost springs avaialble if you wish to control even higher levels of boost.

Some cars with very restrictive intercoolers or plumbing may experience a pressure drop and a boost drop at high airflow (rpm), in order to maintain a flat boost line, and to enhance response the following plumbing can be tried. On some cars this may lead to a boost spike, but not always. Alao keep in mind that a if you have a very restrictive intake system you may not want to push it anyway!

|

| |

|